ANU and LONGi shape industry direction for manufacturing high-performance silicon wafers

- Nov 24, 2025

- 4 min read

In recent years, with the support of ACAP, Dr Anyao Liu and the Silicon PV Research Group at ANU have delivered a major body of work that is helping global industry chart the path to cleaner, more efficient and more stable silicon solar technologies.

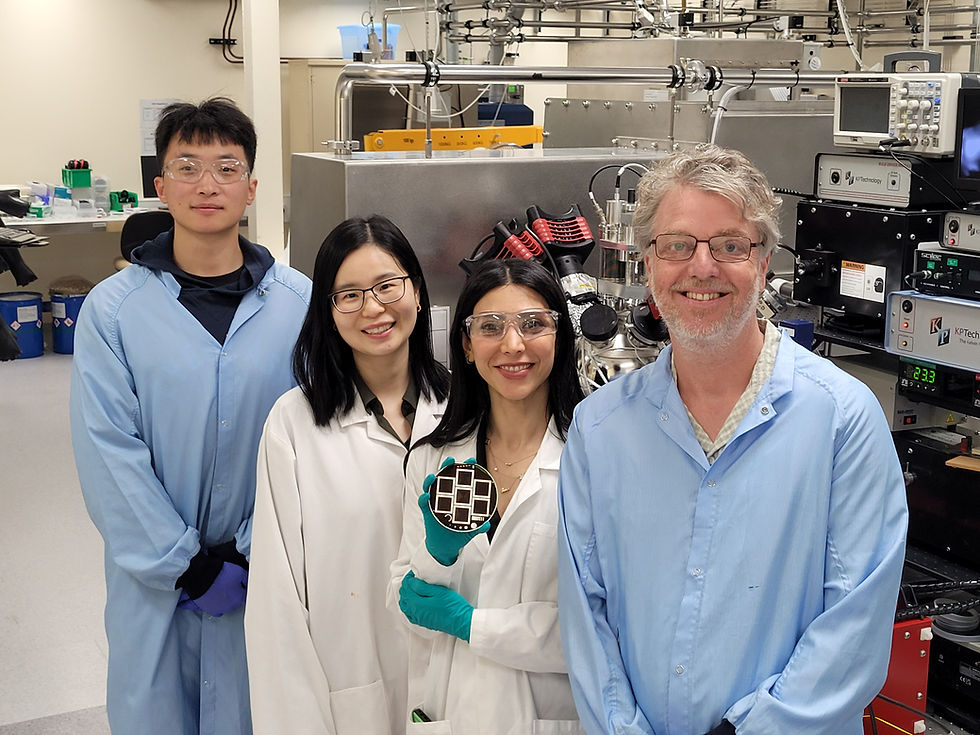

Building on decades of pioneering work at both ANU and UNSW in identifying and eliminating bulk defects in silicon, the ANU team – including Professor Dan Macdonald, Dr Anyao Liu, Dr Rabin Basnet, Ms Afsaneh Kashizadeh, Dr Zhongshu Yang and many former colleagues – has sharpened industry’s understanding of wafer quality, characterisation methods, and defect-control strategies that are central to next-generation solar manufacturing.

A major 2021 step was a comprehensive review of gettering in silicon photovoltaics[1] – a full map of how manufacturers can remove metal impurities to less harmful regions of the device during solar cell production. As solar cell efficiency continues to rise, materials are becoming far more sensitive to even tiny traces of contamination. Dr Liu and the team mapped out all gettering techniques applicable to silicon solar cells, including some pioneered by the ANU team, and provided the first comprehensive picture of how manufacturers can optimise these steps as the industry moves to higher purity requirements. Their findings reinforced ANU as a trusted voice in guiding how cleaner, more reliable wafers can be produced at scale.

The team’s 2024[2] investigation of iron contamination impacts in TOPCon cells provides practical pathways for manufacturers to better manage impurities and stabilise cell performance. They confirmed the robustness of TOPCon and highlighted how advanced gettering helps maintain performance as efficiencies increase.

In parallel, the ANU team advanced understanding of the emerging recharged Czochralski (RCz) crystal-growth method (2024)[3]. This work showed that RCz silicon can achieve exceptional purity and consistency, even after multiple reuses of the melt, providing confidence that high-volume, energy-efficient production can still deliver world-class material quality.

In 2025 the ANU team delivered cutting-edge investigations focused on the emerging antimony-doped (Sb-doped) n-type silicon[4][5]. The researchers demonstrated that Sb-doped wafers show more uniform electrical behaviour along the ingot and exhibit excellent quality that is mostly at the intrinsic limit.

These breakthroughs were made possible through ANU’s close collaboration for the past three years with LONGi, one of the world’s largest producers of silicon wafers for solar PV. As Dr Liu explains, “LONGi is able to grow the new silicon materials, and we have the expertise to provide in-depth characterisation and analysis. Together we are making valuable progress.”

Taken together, ANU’s program of work provides the industry with a clear pathway towards cleaner, and more consistent n-type wafers, delivering higher efficiencies. As Dr Basnet concludes, “These findings indicate that Sb-doped n-type Cz wafers are considered a strong candidate to become the industry standard for the next generation of n-type wafers.”

“These findings indicate that Sb-doped n-type Cz wafers are considered a strong candidate to become the industry standard for the next generation of n-type wafers.”

Dr Liu reflects, “It’s exciting to think our work can have a direct impact on the solar industry, driving real world progress in renewable energy, and shaping the future of solar technology.”

With ACAP’s support, ANU and LONGi have positioned Australia at the forefront of high performance silicon wafer research that is directly shaping the future of global solar manufacturing.

[1] Gettering in silicon photovoltaics: a review, AnYao Liu, Sieu Pheng Phang, Daniel Macdonald, Solar Energy Materials and Solar Cells, Volume 234, January 2022, 111447, https://doi.org/10.1016/j.solmat.2021.111447

[2] Effect of Iron Contamination and Polysilicon Gettering on the Performance of Polysilicon-Based Passivating Contact Solar Cells, Zhongshu Yang, Rabin Basnet, Chris Samundsett, Sieu Pheng Phang, Thien Truong, Di Kang, Wensheng Liang, Anh Dinh Bui, Wei Wang, Tien T. Le, Daniel Macdonald, AnYao Liu, Prog Photovolt Res Appl, 33: 463-476, 26 November 2024 https://doi.org/10.1002/pip.3873

[3] Auger-limited bulk lifetimes in industrial Czochralski-grown n-type silicon ingots with melt recharging, Afsaneh Kashizadeh, Rabin Basnet, Lachlan Black, Christian Samundsett, Chang Sun, Qian Jin, Yichun Wang, Hao Deng, Daniel Macdonald, Solar Energy Materials and Solar Cells, Volume 277, 15 October 2024, 113143, https://doi.org/10.1016/j.solmat.2024.113143

[4] High Quality Antimony-Doped n-Type Silicon Wafers for Solar Cell ApplicationsAfsaneh Kashizadeh, Rabin Basnet, AnYao Liu, Zhongshu Yang, Lachlan Black, Chang Sun, Wei Han, Yichun Wang, Daniel Macdonald, Solar RRL, Volume 9, Issue 17 2500335, 05 August 2025, https://doi.org/10.1002/solr.202500335

[5] Resistivity distribution and donor properties of antimony-doped n-type Czochralski silicon ingots Rabin Basnet, Chirag Mule, Wei Han, Nannan Fu, Afsaneh Kashizadeh, P. Craig Taylor, Sumit Agarwal, Yichun Wang, Paul Stradins, Daniel Macdonald, Solar Energy Materials and Solar Cells, Volume 295, 15 January 2026, 114018, https://doi.org/10.1016/j.solmat.2025.114018

Good material. Great work.👍Wish you all the best.